INTRO

Cold chain supply is becoming an increasingly important part of logistics as many of our products are delivered frozen. Unfortunately, it can be a challenge for the fleet manager to monitor the temperature in the trailer as it travels, so ensuring the quality of the chilled goods becomes a real headache. Fortunately, GPS devices can help by providing the fleet manager with relevant information about the situation inside the reefer trailer.

CHALLENGE

In cold chain logistics, challenges can arise at 3 different stages. Firstly, the product could be damaged before it starts its journey, while it is not in the hands of the carrier. Secondly, its quality could deteriorate during transport due to incorrect temperature settings, refrigerator doors not being closed, condensation, etc. Thirdly, the condition of the goods may deteriorate once they are in the recipient's care because they may be stored in an inappropriate environment.

All refrigerated goods need to be kept at a specific temperature throughout their journey. Even small changes in temperature can affect either the quality of the goods or the environment in which they are stored, which in turn can affect the products themselves. Incorrect temperature settings can increase the risk of microbial or mould growth in the hold, or if the temperature is too low, it can damage the product by forming larger groups of ice crystals on it.

Another area that presents many challenges is the doors on reefer fridges. Damaged doors can fail to close completely, allowing warm temperatures in and cold temperatures out. Even if the temperature settings are correct, this will affect the temperature inside the reefer and the damage may be irreversible, costing the transport company a lot of money. This type of problem can even affect the safety of workers, as the inside of the trailer can become slippery or covered in unhealthy mould.

It is also important to have accurate data about the environment in a trailer. The recipient of the goods, or a regulatory body, may ask for this data if the products are found to be damaged on delivery. And it would be a big problem if the data showed that the environment in which the products were stored had affected their quality. The fleet manager needs to know at all times that the goods are being stored in appropriate conditions to avoid potential difficulties with the recipient, and Teltonika Telematics can help.

SOLUTION

Teltonika PROFESSIONAL series vehicle GPS trackers FMC650 and FMM650 can read data from freezer trailer thermographs. This data would allow fleet managers to monitor the situation inside the reefer as it travels and give further instructions to the drivers if any changes need to be made. As a result, more goods would be stored in the reefer in proper conditions, ensuring that their quality does not deteriorate during transport. To further demonstrate the solution, we use FMC650 model.

How it works - a freezer thermograph is a device that measures the temperature in the trailer, while also storing data about the environment in the reefer trailer for further use and analysis. Thermographs that our devices support have an RS232 communication line which can be connected to our FMC650 tracker via COM1/COM2 port. Once connected, our device can start monitoring and storing the data recorded by the thermograph.

As the two devices are easy to connect and configure, it becomes a perfect solution for transport companies operating in the cold chain supply industry. In addition, Teltonika PROFESSIONAL series supports three different types of thermographs – Carrier DataCold 600, Thermo King Transcom 2, and Thermo King TouchPrint.

FMC650 allows a fleet manager to monitor thermograph data live as the tracker sends this data directly to the server. As one of the main uses of the thermograph is to record temperature data, the GPS device also tracks this data. This leads to the possibility of changing some of the freezer settings while on the road. If the fleet manager notices that the temperature is too low or too high, he can call the driver and ask him to adjust the temperature in the reefer. This ensures that the goods are always stored in the proper environment.

Thermographs also monitor the status of refrigerator doors and send data if the doors are not closed properly. FMC650 tracker also collects this data and sends it to the server. As with the temperature, a fleet manager can notify the driver that the fridge doors are not closed properly, and the driver can then close them to prevent potential damage to the goods, people in the surroundings or himself/herself.

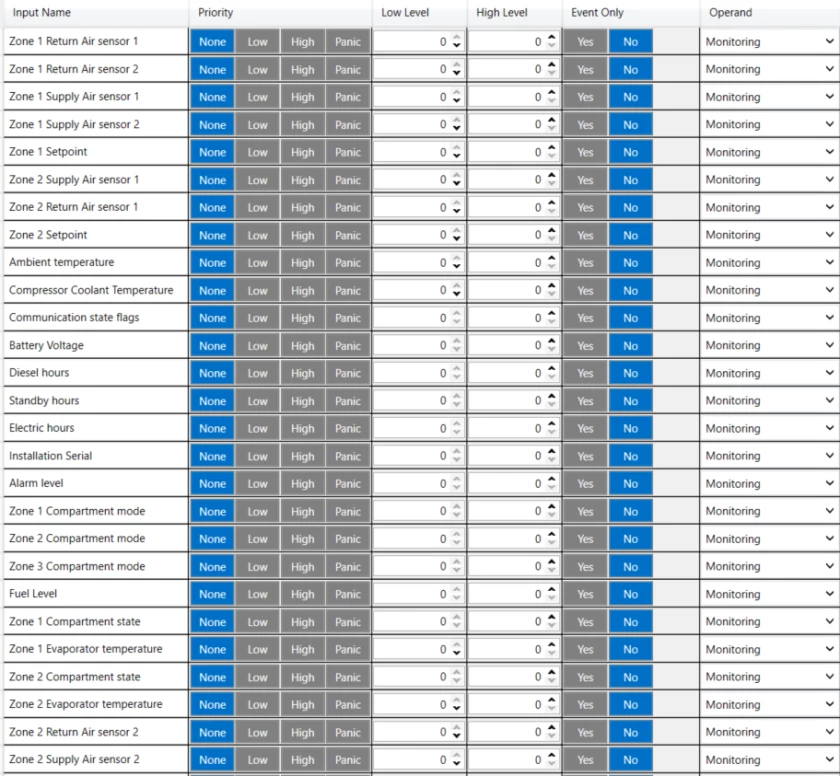

Thermographs also have specific alarms, such as a rapidly rising temperature in a refrigerated vehicle. In addition, Teltonika GPS devices can monitor these alarms and send a notification to the fleet manager that one or more alarms are active. Teltonika PROFESSIONAL series vehicle trackers can be configured to only track certain alarms. Above is a screenshot of Teltonika Configurator setup option. Please note that the exact set of features depends on the specific thermograph model.

If, in the future, the fleet manager needs information about the environment inside the refrigerated trailer, this data can be stored on the server for later access. This functionality is useful if the recipient of the goods or regulatory bodies wants to know the environment in which the goods were stored during transportation.

Teltonika PROFESSIONAL series trackers, namely FMC650 and FMM650, have been designed to help fleet managers meet the above challenges. With these GPS devices, we can offer a complete solution. Let's take FMC650 as an example to show you how.

FMC650 (4G LTE Cat 1) tracker can be configured to generate specific events according to business needs. These events can have different priorities, so the fleet manager would see the events that are most important to them first. This is a handy feature that helps telematics service providers and integrators focus first on the events that are critical to the overall operation of a fleet.

And let's not forget the other features and benefits of these PROFESSIONAL vehicle GPS trackers. They have an RS232 transparent mode that allows data to be easily read from external devices. FMC650 also has an internal 550 mAh battery, external GNSS and 4G antennas, 4 DINs and DOUTs, and its data transmission frequencies can be configured to send data according to different movement scenarios.

TOPOLOGY

BENEFITS

- Accurate temperature monitoring - these trackers enable real-time temperature monitoring, ensuring that perishable goods are transported within the required conditions, reducing spoilage and loss.

- Improved route efficiency - with real-time GPS tracking, fleet managers can optimise routes for faster and more efficient deliveries, which is critical in time-sensitive cold chain logistics.

- Advanced vehicle diagnostics - the FMx6 series provides detailed vehicle diagnostics, enabling predictive maintenance and reducing the risk of breakdowns during critical transport operations.

- Real-time alerts and notifications - receive instant alerts for temperature deviations, unplanned stops or door openings, enabling immediate corrective action to protect cargo integrity.

- Enhanced regulatory compliance - the FMx6 trackers help meet strict regulatory requirements for temperature-controlled transport, essential for maintaining industry standards and customer confidence.

- Robust data analysis - access to historical data and analysis helps optimise future operations, improving overall efficiency and reducing operational costs.

- Increased customer satisfaction - by ensuring the integrity of goods and timely deliveries, these trackers help to build a reputation for reliability and quality service in the cold chain logistics sector.

WHY TELTONIKA?

At Teltonika Telematics, innovation is at the heart of everything we do. Our FMx6 series trackers are not just devices; they are comprehensive monitoring solutions that enable businesses to maintain tight control over their cold chain logistics. This level of precision and reliability is essential in a sector where even small temperature fluctuations can have a significant impact on product quality.

These GPS tracking devices provide real-time temperature data, door status alerts and detailed trip logs, enabling proactive management and quick response to any issues. By choosing us, companies not only comply with stringent industry standards but also improve their operational efficiency and safeguard their reputation for quality and reliability.

Featured product

FMC650Reliable 4G connection with fallback 2G network ensures wide-ranging coverage for your fleet management needs. FMC650 uses a separate module to gather GNSS data and has dual-channel, L1 + L5 support.

Tachograph live data reading via K-Line, ALL-CAN, Tacho CAN or FMS connections for everyday driver management and fleet efficiency

Read J1939 data that includes standard CAN FMS from heavy vehicles like trucks and raw J1939 data from special machinery, such as construction cranes or electric buses. Possibility to connect to CAN line with multiple nodes.

2x RS232 and 1x RS485 serial communication interfaces for connecting external devices, such as thermographs, sensors, RFID readers and more