ВСТУПЛЕНИЕ

Холодовая цепь становится все более важной частью логистики, поскольку многие наши продукты доставляются замороженными. К сожалению, менеджерам автопарков может быть непросто отслеживать температуру в прицепах во время движения, поэтому обеспечение качества охлажденных товаров превращается в настоящую головную боль. К счастью, устройства GPS могут помочь, предоставляя менеджерам автопарков соответствующую информацию о ситуации внутри рефрижераторных прицепов.

ПРОБЛЕМА

В логистике холодовых цепей проблемы могут возникать на 3-х различных этапах. Во-первых, продукт может быть поврежден до того, как он отправится в путь, пока он не находится в руках перевозчика. Во-вторых, его качество может ухудшиться во время транспортировки из-за неправильных настроек температуры, незакрытых дверей холодильника, образования конденсата и т.д. В-третьих, состояние товара может ухудшиться после того, как он окажется в руках получателя, поскольку может храниться в неподходящих условиях.

Все охлажденные товары должны храниться при определенной температуре на протяжении всего пути следования. Даже небольшие изменения температуры могут повлиять либо на качество товаров, либо на окружающую среду, в которой они хранятся, что, в свою очередь, может повлиять на сами продукты. Неправильная настройка температуры может увеличить риск размножения микробов или плесени в камере хранения, а если температура слишком низкая, это может повредить продукт, образовав на нем большие группы кристалликов льда.

Еще одна область, в которой возникает много проблем, - это дверцы рефрижераторных холодильников. Поврежденные дверцы могут не закрываться полностью, пропуская внутрь высокую температуру и наружу холодную. Даже если температурные настройки установлены правильно, это повлияет на температуру внутри рефрижератора, и ущерб может быть необратимым, что обойдется транспортной компании крупными потерями. Такого рода проблемы могут даже повлиять на безопасность работников, поскольку внутренняя часть прицепа может стать скользкой или покрыться вредной для здоровья плесенью.

Также важно иметь точные данные об окружающей среде в прицепе. Получатель товара или регулирующий орган могут запросить эти данные, если при доставке будет обнаружено, что товары повреждены. И было бы большой проблемой, если бы данные показали, что среда, в которой хранились продукты, повлияла на их качество. Менеджеры автопарков должны всегда знать, что товары хранятся в надлежащих условиях, чтобы избежать потенциальных трудностей с получателем, и Teltonika Telematics может в этом помочь.

РЕШЕНИЕ

Автомобильные GPS-трекеры Teltonika серии PROFESSIONAL FMC650 и FMM650 могут считывать данные с термографов прицепов-морозильников. Эти данные позволили бы руководителям автопарков отслеживать ситуацию внутри рефрижераторов во время их движения и давать дальнейшие инструкции водителям, если потребуется внести какие-либо изменения. В результате в рефрижераторах будет храниться больше товаров в надлежащих условиях, гарантируя, что их качество не ухудшится во время транспортировки. Для дальнейшей демонстрации решения мы используем модель FMC650.

Как это работает - термограф для морозильной камеры - это устройство, которое измеряет температуру в прицепе, а также сохраняет данные об окружающей среде в рефрижераторном прицепе для дальнейшего использования и анализа. Термографы, поддерживаемые нашими устройствами, имеют линию связи RS232, которую можно подключить к нашему трекеру FMC650 через порт COM1/COM2. После подключения устройство может начать мониторинг и сохранение данных, записанных термографом.

Поскольку оба устройства просты в подключении и настройке, они становятся идеальным решением для транспортных компаний, работающих в сфере холодовых цепей. Кроме того, серия Teltonika PROFESSIONAL поддерживает три различных типа термографов – Carrier DataCold 600, Thermo King Transcom 2 и Thermo King TouchPrint.

FMC650 позволяет менеджерам автопарков отслеживать данные термографов в режиме реального времени, т.к. трекер отправляет эти данные непосредственно на сервер. Поскольку одним из основных применений термографа является запись данных о температуре, устройство GPS также отслеживает эти данные. Это приводит к возможности изменения некоторых настроек морозильной камеры в дороге. Если менеджер автопарка заметит, что температура слишком низкая или слишком высокая, он может связаться с водителем и попросить его отрегулировать температуру в рефрижераторе. Это гарантирует, что товары всегда будут храниться в надлежащих условиях.

Термографы также отслеживают состояние дверей холодильника и отправляют данные, если двери закрыты неправильно. Трекер FMC650 также собирает эти данные и отправляет их на сервер. Как и в случае с температурой, менеджеры автопарка могут уведомить водителя о том, что дверцы холодильника закрыты неправильно, и затем водитель может закрыть их, чтобы предотвратить потенциальный ущерб товарам, окружающим людям или самому себе.

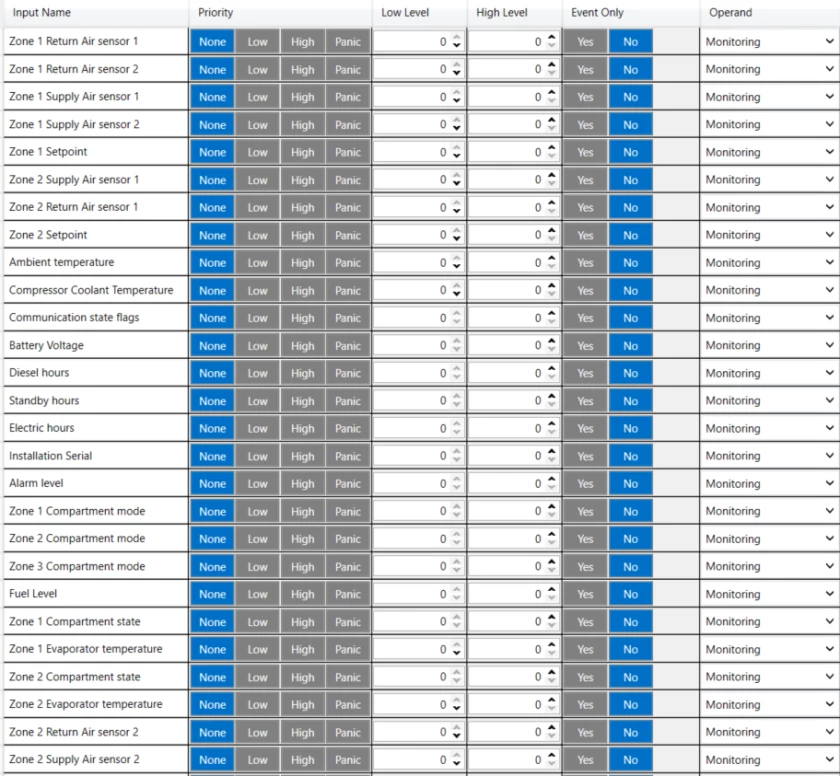

Термографы также имеют специальные сигналы тревоги, такие как быстрое повышение температуры в автомобиле-рефрижераторе. А устройства Teltonika GPS могут отслеживать эти сигналы тревоги и отправлять уведомление менеджерам автопарка о том, что активен один или несколько сигналов тревоги. Автомобильные трекеры серии Teltonika PROFESSIONAL можно настроить для отслеживания только определенных аварийных сигналов. Выше приведен скриншот настройки Teltonika Configurator. Пожалуйста, обратите внимание, что точный набор функций зависит от конкретной модели термографа.

Если в будущем менеджерам автопарка потребуется информация об окружающей среде внутри прицепа-рефрижератора, эти данные могут быть сохранены на сервере для последующего доступа. Эта функциональность полезна, если получатели товаров или регулирующие органы хотят знать условия, в которых товар хранился во время транспортировки.

Трекеры Teltonika серии PROFESSIONAL, а именно FMC650 и FMM650, были разработаны для того, чтобы помочь менеджерам автопарков справиться с вышеуказанными задачами. С помощью этих GPS-устройств мы можем предложить комплексное решение. Давайте рассмотрим FMC650 в качестве примера, чтобы показать вам, как это сделать.

Трекер FMC650 (4G LTE Cat 1) может быть сконфигурирован для генерации конкретных событий в соответствии с потребностями бизнеса. У этих событий могут быть разные приоритеты, поэтому менеджеры автопарков в первую очередь увидят наиболее важные для них события. Это удобная функция, которая помогает поставщикам телематических услуг и интеграторам в первую очередь сосредоточиться на событиях, имеющих решающее значение для общей работы автопарка.

Не будем забывать о других функциях и преимуществах автомобильных GPS-трекеров серии PROFESSIONAL. Они имеют прозрачный режим RS232, который позволяет легко считывать данные с внешних устройств. FMC650 также оснащен встроенным аккумулятором емкостью 550 мАч, внешними антеннами GNSS и 4G, 4 DIN и DOUT, а его частоты передачи данных могут быть сконфигурированы для отправки данных в соответствии с различными сценариями перемещения.

ТОПОЛОГИЯ

ПРЕИМУЩЕСТВА

- Точный контроль температуры - трекеры позволяют контролировать температуру в режиме реального времени, обеспечивая транспортировку скоропортящихся продуктов в требуемых условиях, что снижает их порчу и потери.

- Повышение эффективности маршрутов - благодаря GPS-навигации в режиме реального времени менеджеры автопарков могут оптимизировать маршруты для более быстрой и эффективной доставки, что очень важно для логистики холодовых цепей, чувствительных к времени.

- Расширенная диагностика транспортного средства - серия FMx6 обеспечивает подробную диагностику транспортных средств, позволяя проводить прогнозируемое техническое обслуживание и снижая риск поломок во время критически важных транспортных операций.

- Оповещения и уведомления в режиме реального времени - мгновенное оповещение об отклонениях температуры, незапланированных остановках или открытии дверей, что позволяет немедленно принять меры по исправлению ситуации для защиты целостности груза.

- Повышенное соответствие нормативным требованиям - трекеры FMx6 помогают соответствовать строгим нормативным требованиям к перевозкам с контролем температуры, что важно для поддержания отраслевых стандартов и доверия клиентов.

- Надежный анализ данных - доступ к истории данных и их анализ помогают оптимизировать будущие операции, повышая общую эффективность и снижая производственные расходы.

- Повышение удовлетворенности клиентов - гарантируя целостность товаров и своевременную доставку, трекеры помогают создать репутацию надежного и качественного поставщика услуг в секторе логистики холодовых цепей.

ПОЧЕМУ TELTONIKA?

В Teltonika Telematics инновации лежат в основе всего, что мы делаем. Наши трекеры серии FMx6 - это не просто устройства; это комплексные решения для мониторинга, которые позволяют предприятиям поддерживать жесткий контроль над логистикой своих холодовых цепей. Такой уровень точности и надежности необходим в отрасли, где даже небольшие колебания температуры могут оказать значительное влияние на качество продукции.

Эти устройства GPS-слежения предоставляют данные о температуре в режиме реального времени, оповещения о состоянии дверей и подробные журналы поездок, обеспечивая проактивное управление и быстрое реагирование на любые проблемы. Выбирая нас, компании не только соблюдают строгие отраслевые стандарты, но и повышают эффективность своей работы и защищают свою репутацию качества и надежности.

Рекомендуемый продукт

FMC650Надежное соединение 4G с возможностью возврата к сети 2G обеспечивает широкое покрытие сетей для управления автопарком. Данная модель использует отдельный модуль для сбора данных GNSS и имеет двухканальную поддержку L1 + L5.

Считывание данных с тахографа в реальном времени через соединения K-Line, ALL-CAN, Tacho CAN или FMS для ежедневного управления водителями и повышения эффективности автопарка

Возможность чтения данных J1939, включающих FMS стандарт от тяжелых транспортных средств, таких как грузовики, и необработанные данные J1939 от специальной техники, например, строительных кранов или электробусов. Возможность подключения к линии CAN с несколькими узлами.

Наличие 2x RS232 и 1x RS485 последовательных интерфейсов связи для подключения внешних устройств, таких как термографы, датчики, RFID считыватели и т.д.